CNC USES

CNC

Applications

UNICAM CNC

industrial CNC

Use-cases

1

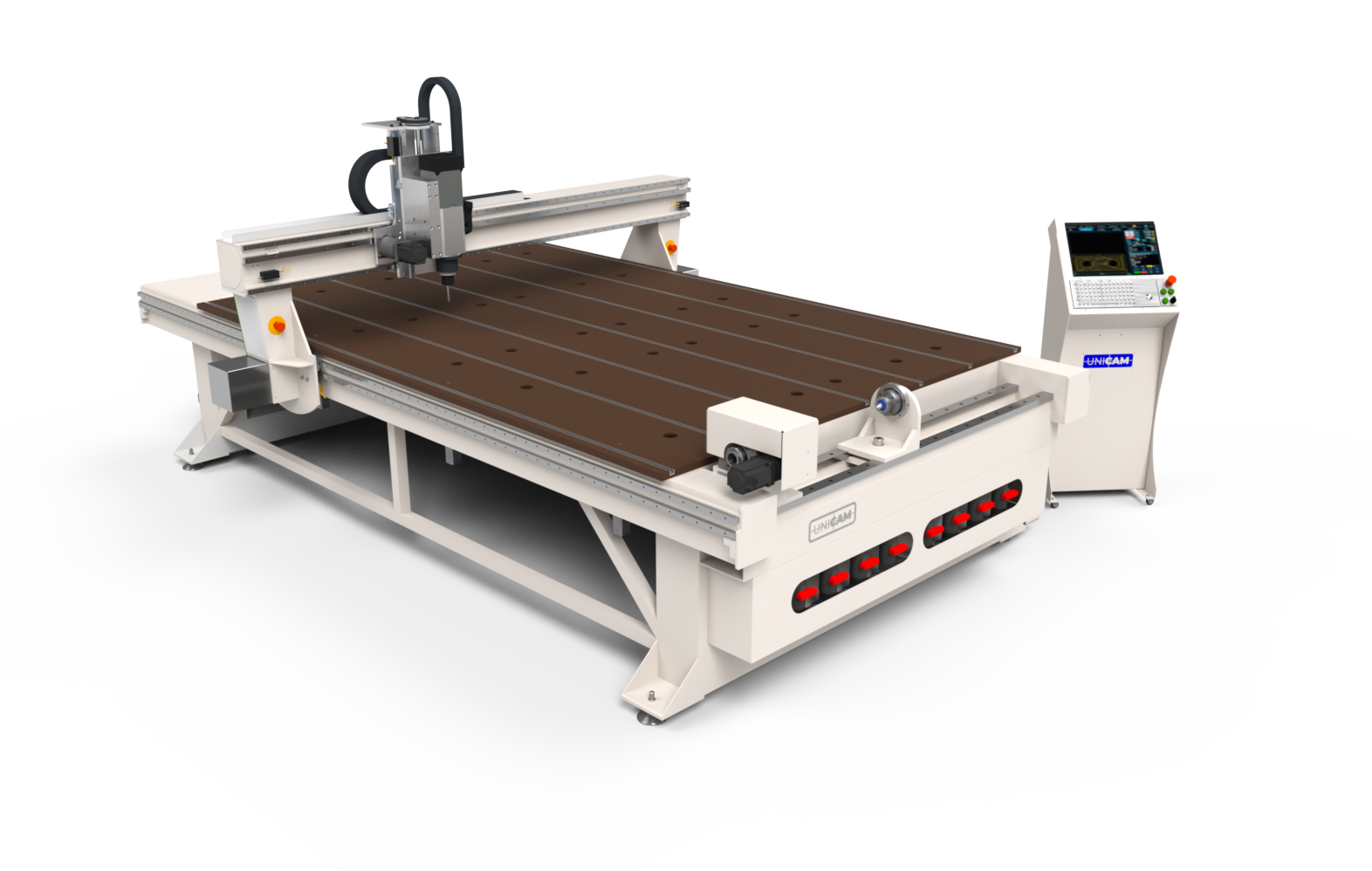

Excalibur

CNC Machine

Multi-purpose

Unicam’s Nesting Router (can have up to 5 Axises) optimizes table space for cutting or machining on any of an material’s avail- able faces however it is mostly used for working with flat materials. The flat table can machine from the top and, by using an aggregate unit can also machine the Y axis vertical faces, or use a saw blade. Adding a C-Axis to the spindle it can machine any angular vertical faces. Any surface angle can be machines with a Bi-Rotary spindle.

2

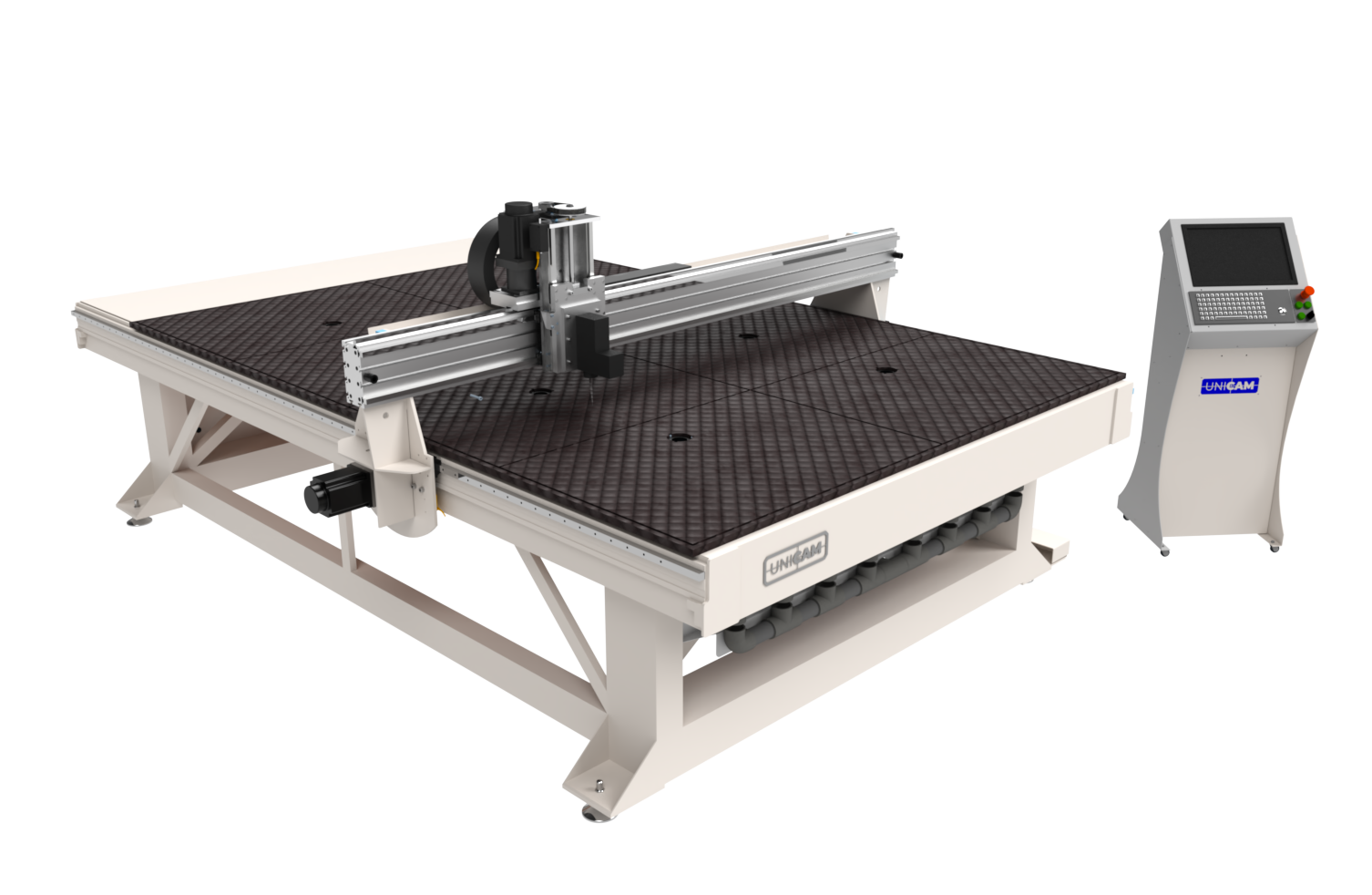

UNISAW

CNC MACHINE

aluminum extrusion

Precise and high speed cutting to length of materials such as Aluminium, wood, Non-Ferrous metals, PVC, Vesconite. This machine uses a carbide tipped blade that moves vertically to cut the material. The material is clamped on both sides of the blade and at the rear mounting. The material is indexed using a servo motor and the position is moved relative to the absolute position of the machine, obviating any accumulative error.

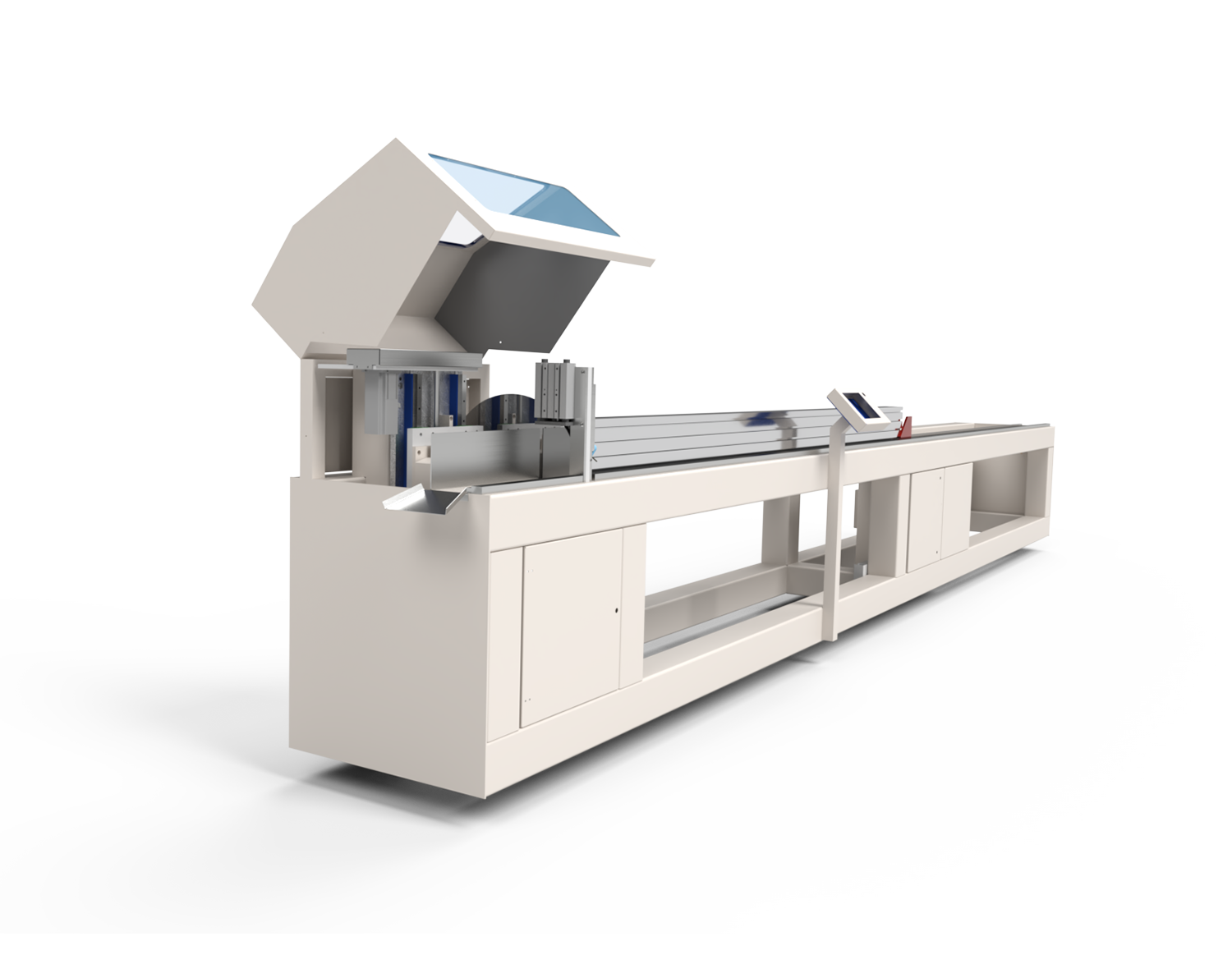

3

stonemaster

CNC MACHINE

stonework

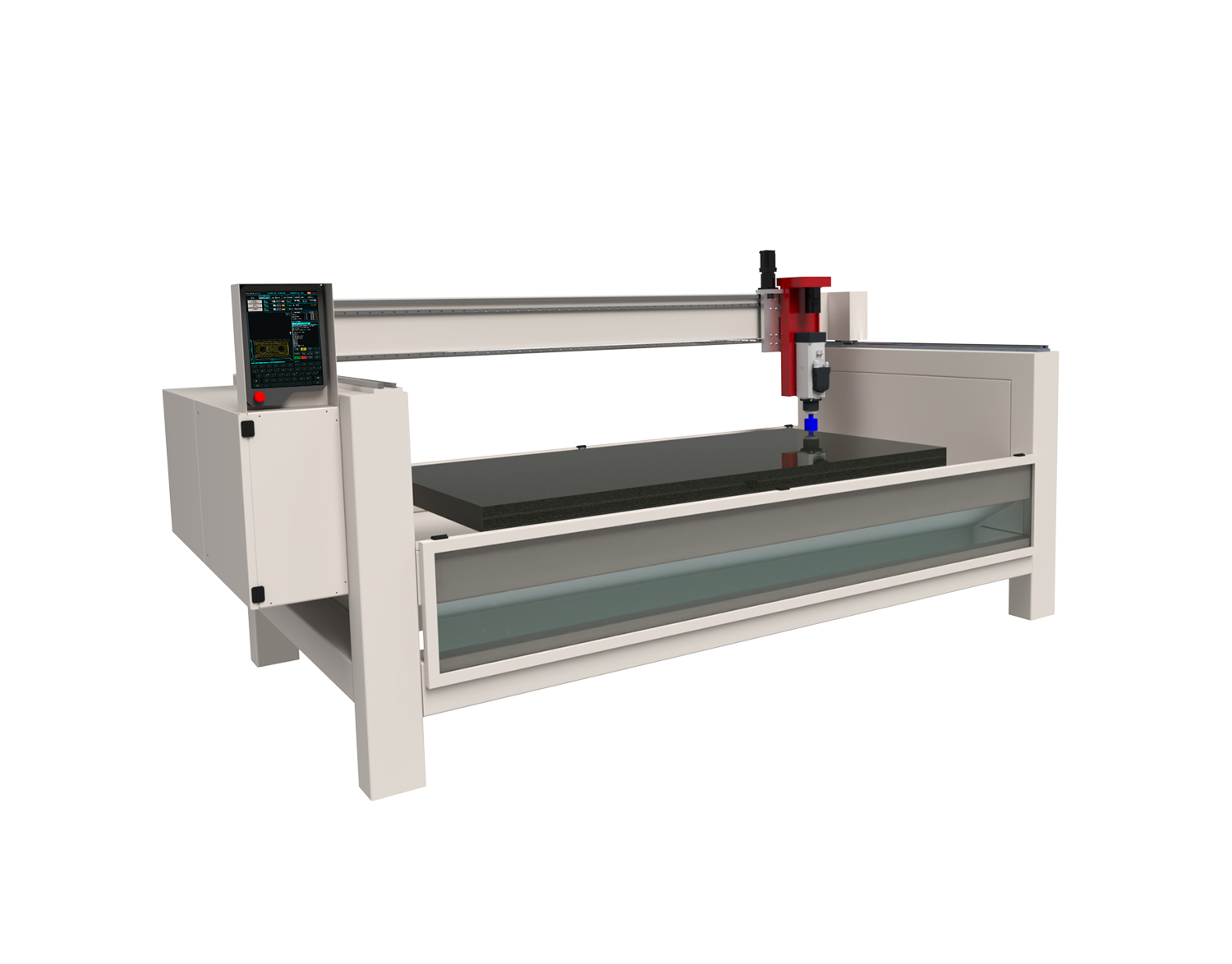

Made for cutting/carving/engraving Stone (marble/granite). This CNC unit cuts kitchen tops, bathroom counters, furniture, headstones; or simply creating beautiful things out of stone. We use a special Hiteco spindle that feeds water through the cutter (which keeps the cutter cool for longer tool life). This unit can be a 3 or 4 axis machine, the fourth axis can be used to rotate an aggregate head so that the operator can use a saw-blade to cut at any angle.

Quality

which industries

are best suited

for one of Unicam’s CNC Machines?

ALUMINIUM WORK

CNC routers operate with high precision and accuracy. This is particularly crucial when working with aluminum, which is known for its lightweight and soft characteristics. The ability to achieve tight tolerances ensures that intricate details and complex geometries can be machined with consistency.

FURNITURE MAKING

Making furniture using a CNC router, is one of Unicam mean machine’s most popular applications. Our CNC Routers can be equipped with routing, boring, grooving, planning and sanding tools and are capable of simultaneous movements on symmetrical planes using multiple heads and automatic tool changers. These CNC routers are often referred to as nesting machines and provide a complete solution for furniture making with a CNC router.

sign MAKING

One of the best uses for a CNC router is producing signs. Sign making using a Unicam CNC router can automate and increase the efficiency of your sign-making process, enabling you to deliver signs to customers on time, always. With traditional sign-making techniques, lettering is manually carved onto the target surface using a v-chisel or power chisel. Even though hand lettering can be used to create decorative signs, there are some restrictions to this method. Traditional carving can be replaced by CNC routers, which can also be used to create high-quality custom signage from a range of materials.

STONEWORK

The Unicam CNC router designed for stone working, can cut, engrave and drill on marble, granite, travertine, limestone, onyx, soapstone, slate, quartzite and more. It is a suitable CNC Machine for fireplaces, countertops, sinks, headstone / tombstones etc. It is compatible with a variety of CAD/CAM design software. It is equipped with professional router bits and a tool cooling system to effectively improve tool lifespan.

DOOR & WINDOW FRAMES

CNC machines provide precise milling and cutting capabilities, allowing for accurate shaping and sizing of doors, window frames & solar panel components. This 100% precision is crucial for ensuring proper fit and alignment during installation.

cabinet making

Cabinetmakers can shorten lead times and minimise material handling using a Unicam CNC router. Small, mid-size, and large firms all can manufacture doors, countertops, shelves, drawer fronts, and other items thanks to our CNC routers. By utilizing just one machine and the appropriate software system, operating a CNC machine enables cabinetmakers to apply a manufacturing process that enhances production time, quality, consistency, and material yield.

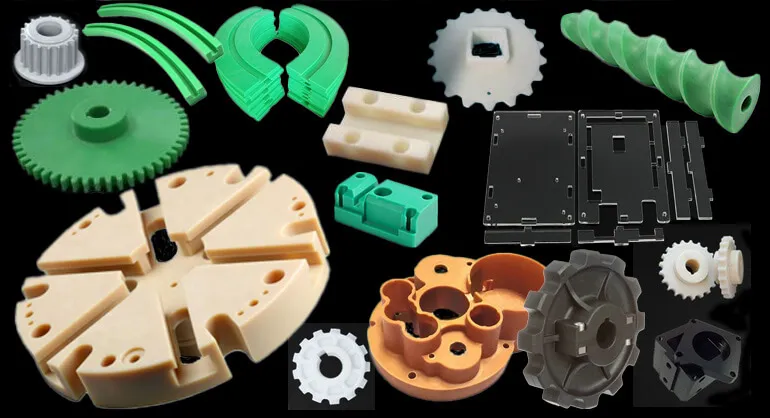

PLASTIC PART MANUFACTURE

Unicam CNC Routers are used in numerous plastic cutting and machining operations. If you are a manufacturer of plastic engineering components, vacuum moulds, liners or inserts, a Unicam CNC router will provide you both economical and reliable performance. High speed cutting the correct chiploads and cooling can prevent the plastics from welding onto the cutter. Technologies such as “through-the-cutter-cooling” can also improve production dramatically.

3D CARVING

CNC machines excel in 3D carving, offering efficiency and precision for intricate designs on doors, window frames, and more. They enable rapid prototyping, consistent reproductions, and customization, making them invaluable for creating unique and detailed surfaces with wood and composite materials.

OUR RANGE

OF CNC MACHINES

Our CNC machines are locally built and internationally specced to compete with all global brands.

UNICAM CNC

First-world Technology.

Industrial Strength.

Built in Africa.

Read lastest

Articles and news

from industry

No posts were found for provided query parameters.

Contact us now

Happy to be

part of team

Lorem ipsum adipiscing dolor elit

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totamet rem aperiam, to eaque ipsa quae ab illo inventore veritatis et quasi.

PHILL AKSERTY

Industry manager

OUR PRODUCTS

OUR STATISTICS

WE ARE ALWAYS

MOVING FOWARD

No posts were found for provided query parameters.

Pharetra convallis posuere leo morbi urna ani molestie. Ac orci phase lus in.

No posts were found for provided query parameters.

Our work

Best projects with

construction

Choose the best quality

metal Cutters

WATCH OUR in-depth

cnc TUTORIALS

read our latest

CNC tips & insights