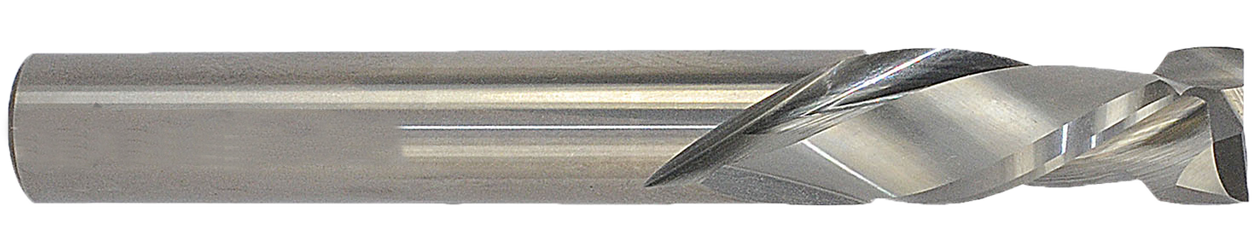

Compression Bits

A compression bit is the combination of both up-cut and down-cut spirals. Typically, a compression spiral has an up-cut single, double, or triple flute at the tip of the cutter, approximately one-third of the cutting length. The remaining two-thirds is ground to give a down-cutting shear.

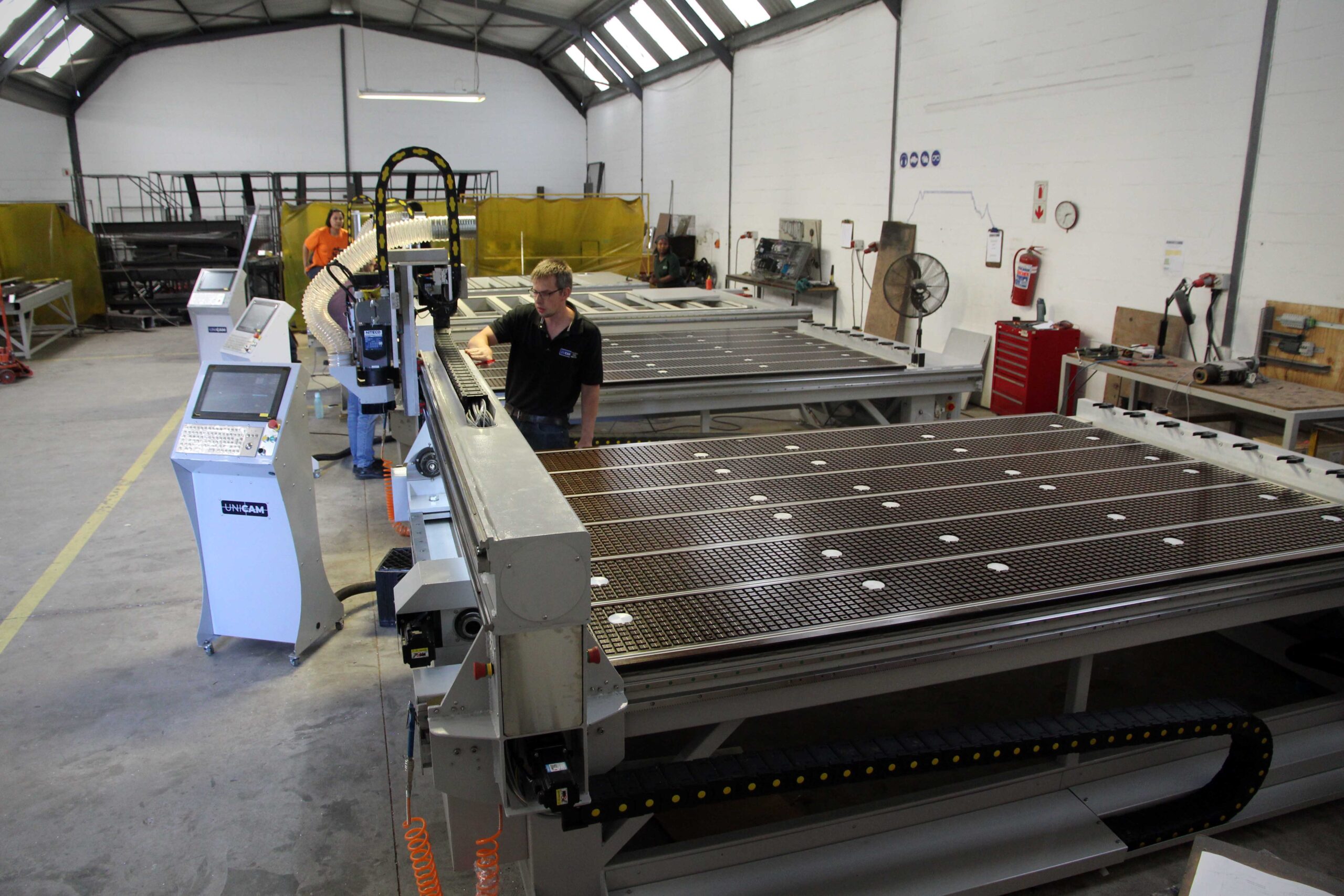

Facts to consider when choosing table size

If you get a light Router Table, then it will vibrate, and you will only be able to cut at a low feed rate or you will break cutters or have rough cutting surfaces. A heavy solid table on the other hand will vibrate less, and this will allow you to run at a higher feed-rate.

Why your Router Table should be Rigid and Heavy

If you get a light Router Table, then it will vibrate, and you will only be able to cut at a low feed rate or you will break cutters or have rough cutting surfaces. A heavy solid table on the other hand will vibrate less, and this will allow you to run at a higher feed-rate.

Absolute, So What?

So, we turn on the mains isolator, and then press the ignition switch… The touch screen comes alive and by the time we have walked to the console the display is up. You look for the familiar ‘Home All Axis’ button and then you realize… there isn’t one. On closer inspection the X, Y, Z readouts have values, this is the position of the machine. The Home buttons have been replaced by Goto Zero buttons. This is the fi

Making Aluminum Parts? Use a Unicam ‘Part-Maker’

The ‘Part-Maker’ is a machine designed to manufacture small aluminum parts such as hinges, clamps, brackets, solar panel mountings, or discreet components from aluminum extrusion or other rigid material. The unit accepts a full length of aluminum extrusion which is fed through a rotary chuck. The machine can be configured with multiple spindles one of which could be an Automatic Tool Changer.

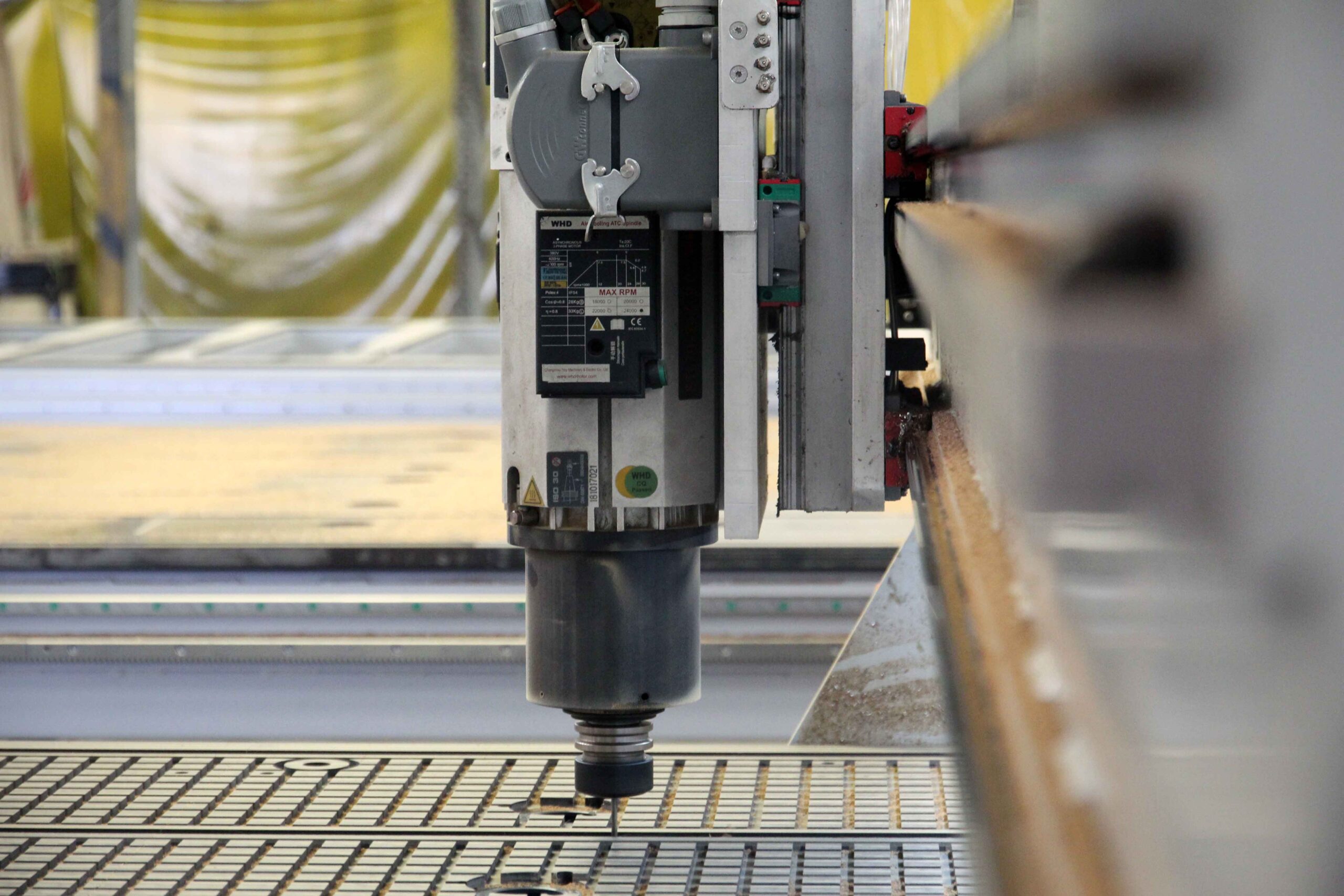

Unicam South Africa – Now agents for Hiteco Spindles

Unicam South Africa uses Hiteco’s world class Spindles as its primary spindle for all its machines, and we are now the Agents for Hiteco Spindles in South Africa. Hiteco are manufactured to cut many types of materials, such as wood, plastics, glass, stone, alloy, steel, and advanced composites. So if you are looking for a specific spindle or just something that will last on your old CNC machine, contact us, and we will f

CNC Machinery: The Key to Survival and Growth for Small Businesses in South Africa

The growth of the manufacturing sector can have a significant impact on South Africa by creating jobs, contributing to economic growth, increasing export earnings, fostering technological advancement, diversifying the economy, and developing skills. This is significant in fueling small business growth.

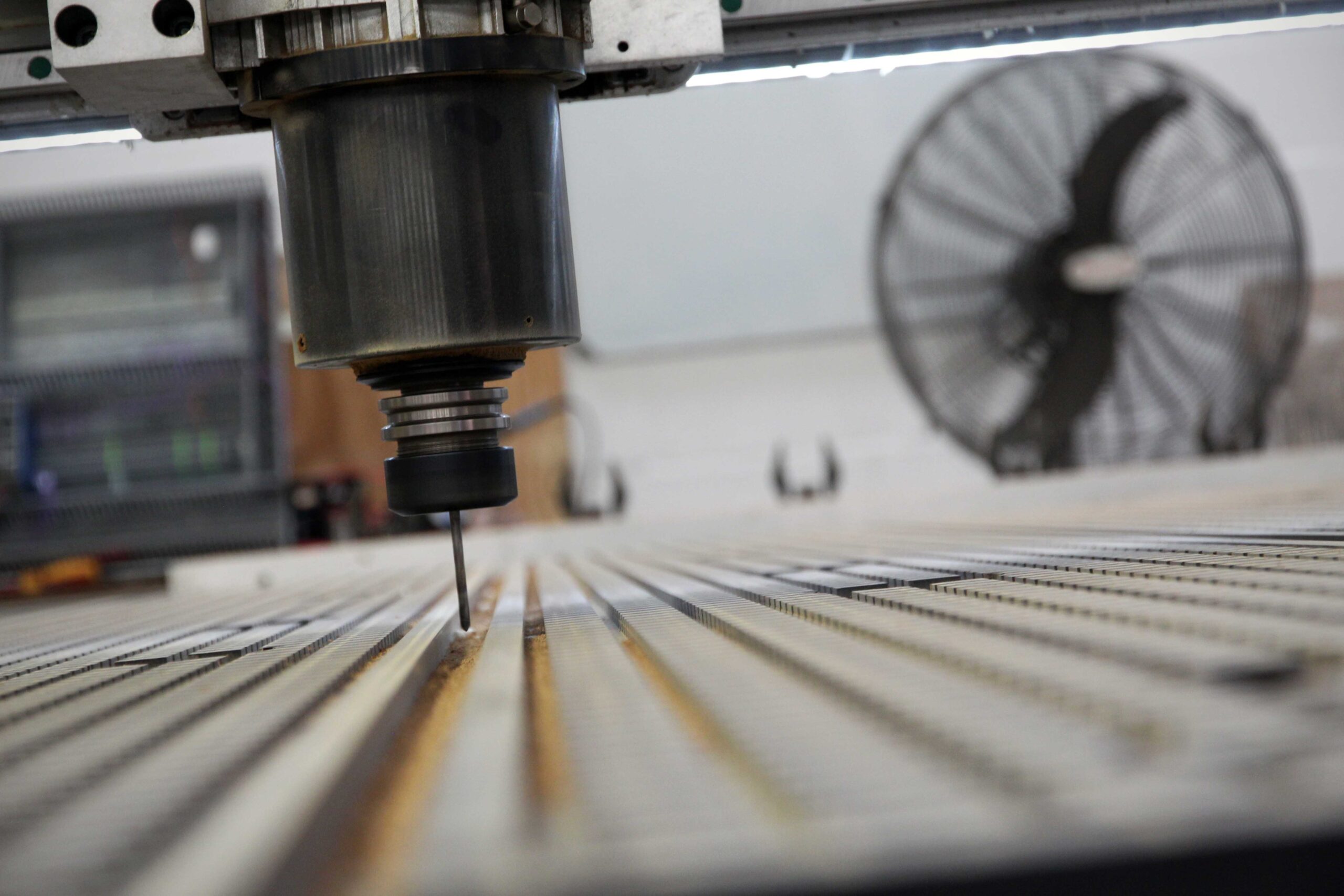

How to choose CNC Router Bits

To use a CNC router, you need a router bit. The bit that you choose determines the type of work you can do, whether it is carving, cutting, surfacing, or grooving. It also determines the finish of your design, and how fast you can cut the material. You achieve different results depending on whether you get up-cut, down-cut straight or compression.

Cutting Aluminum

There are many types of aluminum in two basic conditions. The conditions have more effect on the routing cuts than the types. The conditions are treated, which is hard, and untreated/annealed, which is soft. The hard material forms chips which can be routed much easier than the soft material.

Unicam South Africa Relocates to Larger Premises in Cape Town

Cape Town, South Africa – Unicam South Africa (PTY) Ltd, a leading manufacturer of industrial automation equipment, has recently relocated to a larger space within the same industrial complex in Cape Town. This move comes as the company experiences remarkable growth in spite of the current trend of companies consolidating and downsizing. The unit accepts a full length of aluminum extrusion which is fed through a rotary